The excavator used in coal mines combines the manipulator with the conveyor reasonably, and combines the collection and transportation functions into one. The whole machine adopts an electro-hydraulic control system, and all actions are controlled by a pilot handle. The operation is easy and simple, and the work is stable and impact-free. It has the characteristics of safety and environmental protection, low energy consumption, high efficiency, simple and compact structure, and easy maintenance. Among them, the principle of using electro-hydraulic as the power source has revolutionized the technical status quo of traditional diesel-powered models, solved safety accidents caused by substandard diesel exhaust emissions, and effectively changed the on-site working environment.

The hydraulic system is mainly composed of variable hydraulic plunger pumps, pilot pumps, multi-way valves, hydraulic cylinders, walking motors, manual pilot valves, steel ball motors and other hydraulic components. The various functions of the whole machine are realized through division of labor and cooperation. (Add left and right pilot handles and single-piece handles)

The electrical control system is mainly composed of mine explosion-proof electromagnetic starter, explosion-proof motor, mine explosion-proof LED locomotive lamp, mine explosion-proof sound photoelectric bell, mine explosion-proof emergency stop button, etc. The voltage level is selected according to the user. The above electrical components are in compliance with the certification of the National Mining Product Safety Marking Center, and have obtained the coal safety certificate (MA) and the explosion-proof certificate (EX). (Add LED locomotive lights, explosion-proof sound photoelectric bell)

Application innovation

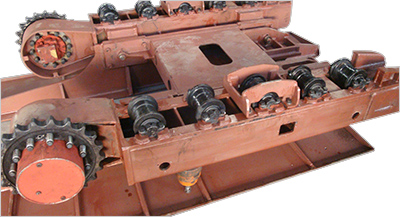

The chassis of this product adopts a three-stage split structure. Under the premise of ensuring the function of the equipment, the chassis part of the equipment is disassembled into three parts and the quick disassembly and installation method (invention patent) is applied, which reduces the transportation and assembly costs of the equipment. It solves the problem that it is difficult to transport or assemble because the chassis part is often too large and heavy when it is transported for a long distance in a tunnel or underground mine (utility model patent).

Under the premise of not changing the equipment's working ability and safety factors, this product through technological innovation of the chassis mechanism, equipment covering parts, cab and other parts, compared with domestic products of the same type, the total height of the product is reduced by 30%. The height is 1.7m (the height of domestic products of the same type is 2.2m). This innovative part greatly increases the passing rate, reduces the turning radius of the product, reduces the potential safety hazards caused by the blockage of the equipment on the roadway, and is more in line with the actual working conditions (appearance patent).

In order to meet various complex working conditions, the walking mechanism of this product has changed the diameter of the guide wheel through a series of innovations, increased the climbing angle between the crawler and the ground plane in the walking mechanism (10°-15°), and increased the equipment passing obstacles. Ability to greatly improve the pass rate of equipment after encountering obstacles. This method is the first in China (utility model patent).